A Game Changer for Manufacturers: Exploring the Benefits of a Label Gap Sensor

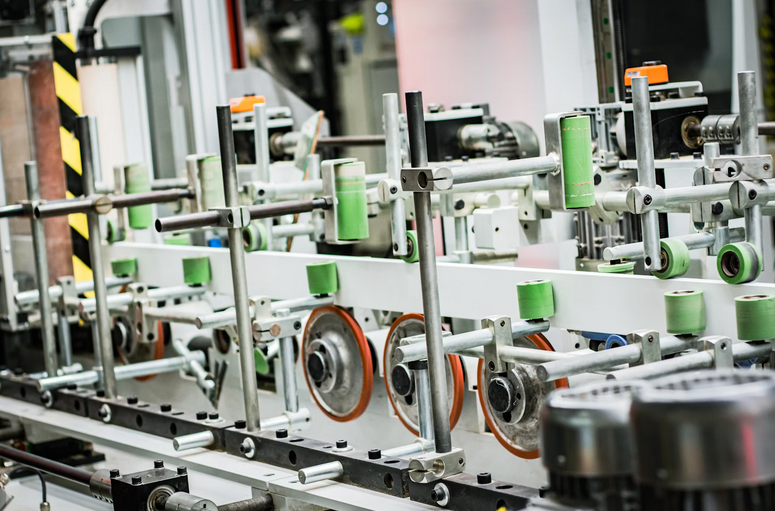

Are you tired of the endless struggle to accurately detect gaps between labels on your manufacturing line? Look no further! We have found the ultimate game-changer for manufacturers – the Leuze Label Gap Sensor.

This ground-breaking technology is revolutionizing the industry, providing unmatched precision and efficiency in label detection. Join us as we explore this sensor’s incredible benefits to manufacturers, unlocking a whole new level of productivity and quality control.

Accurate Label Detection

A label gap sensor offers high precision and accuracy when detecting gaps between labels on a roll. This ensures labels are properly positioned and aligned during the labeling process, reducing errors and improving overall product quality.

Increased Efficiency

The sensor helps streamline the labeling process by accurately detecting label gaps, resulting in increased efficiency. It reduces downtime by preventing mislabeling or double-labeling, ultimately leading to higher production rates and reduced costs.

Easy Integration

The machine is designed for easy integration into existing production lines. It can be easily connected to other equipment, such as label applicators or printing systems, making it a versatile solution for various manufacturing environments.

Real-Time Monitoring

The sensor provides real-time monitoring and feedback on label presence and positioning. This allows operators to quickly identify any issues or deviations in the labeling process and make adjustments promptly, improving overall quality control.

Flexible Label Size Compatibility

The sensor can handle various label sizes, allowing manufacturers to use it across different products and packaging formats. Whether working with small or larger labels, the label gap sensor can adapt to your needs.

Cost Savings

The increased efficiency, reduced waste, and improved accuracy provided by the label gap sensor can result in significant cost savings over time. Manufacturers can optimize production processes, reduce rework, and minimize error-related expenses.

Reduced Waste

Incorrectly applied labels can lead to waste in terms of materials and time. The label sensor helps minimize waste by ensuring precise label placement, minimizing rework, and reducing the need for label scrap or replacements.

Improved Productivity

The sensor frees up operators’ time by automating the label gap detection process, allowing them to focus on more critical tasks. This ultimately leads to improved productivity as human resources can be utilized more efficiently.

Enhanced Customer Satisfaction

Accurate label placement and alignment contribute to overall product aesthetics and help to maintain a consistent brand image. Manufacturers can use the label gap sensor to ensure that their products meet high-quality standards, thereby enhancing customer satisfaction.

In summary, a label gap sensor offers numerous benefits for manufacturers, ranging from increased efficiency and productivity to improved quality control and cost savings. Its high precision and reliability make it an essential tool in the packaging industry, helping manufacturers stay competitive and deliver top-notch products.